Security has always been a concern for architectural designers and project managers, but the nature of the threats that we face in both private and public spaces is changing rapidly. This has mandated a wide-scale reconsideration of how we protect ourselves at home, at work, or in any of the places where we may be vulnerable to firearms-related offenses.

Ensuring that buildings are equipped to deal with real and perceived security threats falls under a key part of the architect’s role: To ensure both functionality and safety of a premise’s design and structural elements. This increasingly means considering bulletproof products such as reinforced windows and forced-entry resistant doors when looking for contractors.

There are numerous considerations to be made as part of the architectural design and construction process, but here are three additional things to bear in mind when it comes to integrating bulletproof products into your designs.

- Market Experience

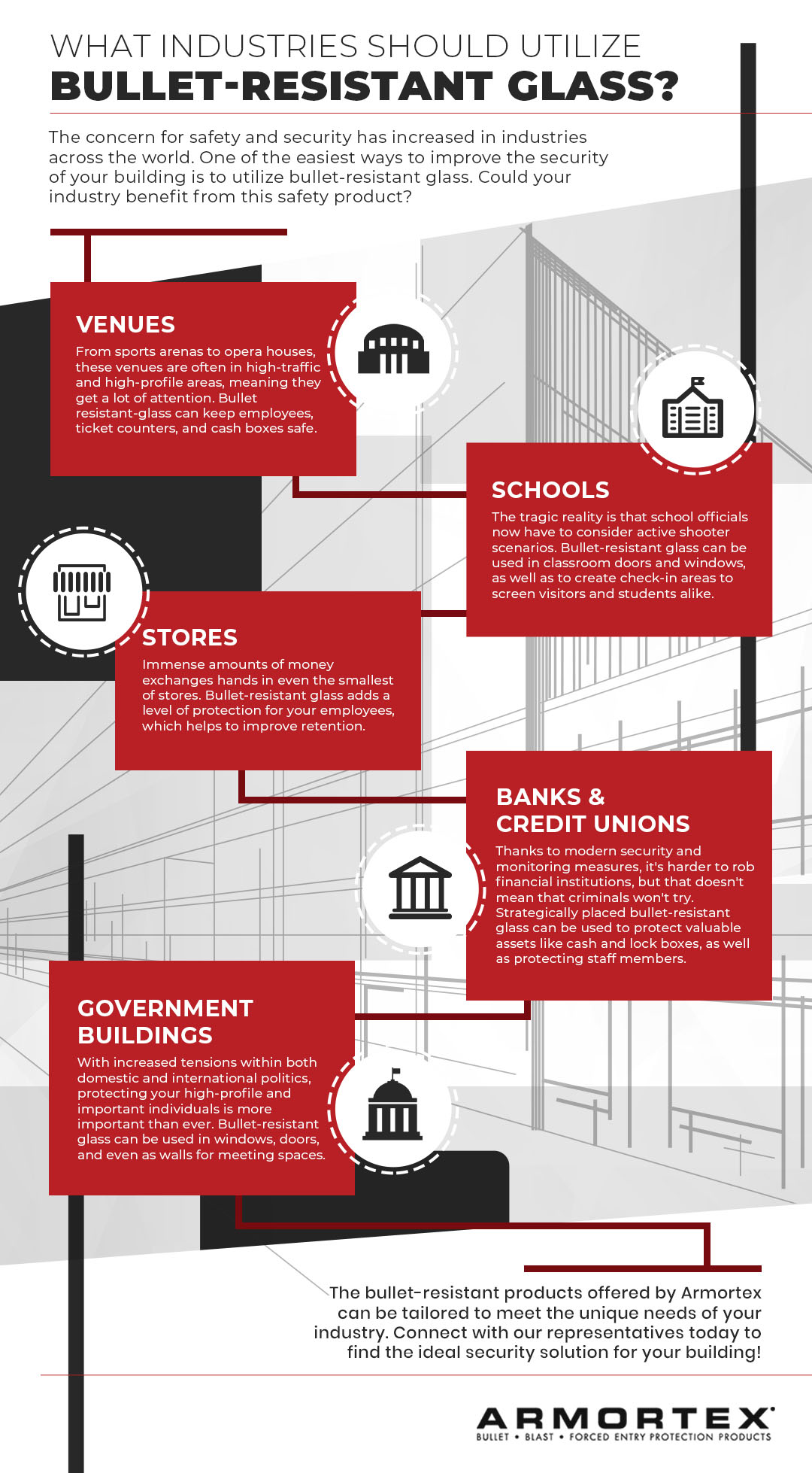

Bulletproof products are increasingly commonplace in a broad range of market sectors from banks and government buildings to convenience stores. We have seen a significant uptick in the number of residential properties that have opted for more robust security solutions from a ballistics perspective, and the growth of bulletproof products for the school security market has been widely reported by mainstream media. Yet there is no one-size-fits-all solution for ballistic, blast, and impact-resistant products.

Find a bulletproof product supplier with significant experience in your target market sector. Can they provide custom veneers to suit your design aesthetic? Do they offer products rated to key specifications (i.e. FEMA)?

- Ballistic Rating

The performance of bulletproof products is typically rated according to Underwriter’s Laboratory (UL) standards, with a 1 – 10 level rating system denoting the severity of impacts that the product can withstand before failure. Your market sector may dictate the level of protection that your project needs, for instance, level 1 is commonly used by small businesses while level 4 and above routinely service high-risk applications (government buildings, military bases, etc.).

If you would like to learn more about this, read our article on Bullet Resistant Glass: Explaining the UL Rating System

- Performance Vs. Load

Generally, high-performance bulletproof products are inherently heavy, which poses design and structural questions. Unlike standard windows, for example, bulletproof windows are comprised of multi-layered polycarbonate composites or glass-clad polycarbonate with reinforced metal frames. This makes them significantly heavier, with higher ballistic-resistant performance corresponding to greater weight.

Experienced bulletproof product contractors understand the need for practicality when it comes to installing new or retrofit security solutions. At Armortex®, we offer a suite of bulletproof solutions that balance security with practicality.

Bulletproof Products from Armortex

Armortex is one of the leading suppliers of high-performance bulletproof products in the US. With a wide range of market expertise and a unique attention to detail when it comes to specific client objectives and requirements, we are the ideal partners for your next architectural project. For more information, simply contact a member of the Armortex team today.